|

|

|

| Customer:

|

Black Diamond Equipment Ltd.

Salt Lake City, UT

|

| Contractor:

|

Direct

|

| Date Completed: |

2000 |

| Scope:

|

Complete Machine Design and Fabrication and Controls Integration |

|

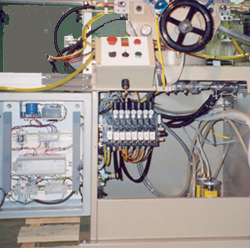

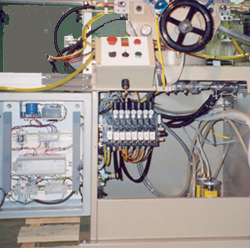

The AD&S automatic controls (left) added on to the factory supplied equipment. |

- Used Off-the-Shelf Equipment with AD&S Modifications

- Eliminated Need for Specialty Cutting Equipment

- Increased Quality and Decreased Cycle Time resulted in

High Through-Put and True Cost-Savings

|

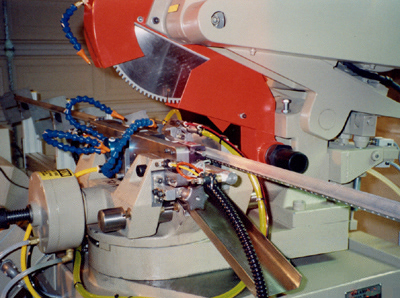

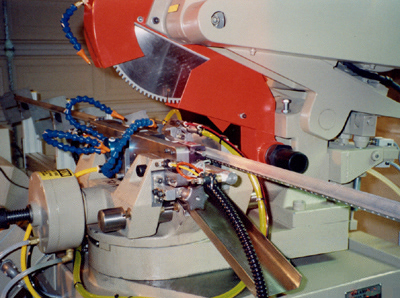

Black Diamond's stopper manufacturing process relied on specially shaped cutting heads that left rough edges and were expensive to purchase and maintain.

AD&S designed and built an automated miter saw that started with an off-the-shelf chop saw. Automated controls, sensors, and actuators were addes to make the process fully automatic. The new saw cut more cleanly

and used readily available carbide blades for aluminum stock.

- Allen Bradley PLC

- Automatic Bar Feeding and Ejection

- Automatic Mitering with

Standardized Aluminum Cutting Tools

|

The standard Kalamazoo miter saw with modified jaws and actuators. |

|